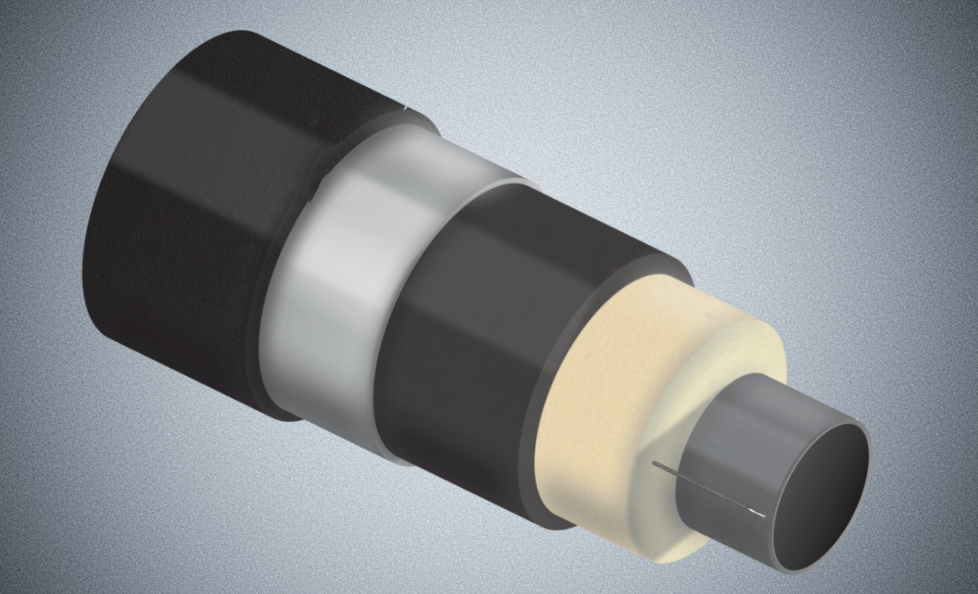

RADPOL offers a unique solution: a complete anti-diffusion system. Due to this decision, the reduction of heat transfer losses reaches as much as 15% during the first 10 years of operation of the pipelines.

Innovative technology using EVOH material, which is placed in the shell of the pipe body (between two layers of modified HDPE), ensures that the thermal conductivity of the insulation remains almost unchanged during the operation of the heating pipe for up to 30 years. Due to this solution, the service life of the heating pipe is extended.

Advantages of insulated pipes with a diffusion barrier:

- Longer operating period of centralized heat supply networks due to the composite properties of the insulated pipe.

- Practically unchanged level of insulation properties throughout the entire period of operation of the centralized heating system.

- Lower than usual heat transfer losses, reduces the amount of energy required for heat production, and at the same time the level of CO2 emission into the atmosphere (reduction of the greenhouse effect).

- Ability to supply heat over longer distances without experiencing heat loss.

- A wide selection of manufactured pipe dimensions, diameter from DN20 to DN1000, and standard length — 6 m, 12 m or 16 m.

- In case of need, it is possible to produce insulated pipes of non-standard dimensions.

Appendixes